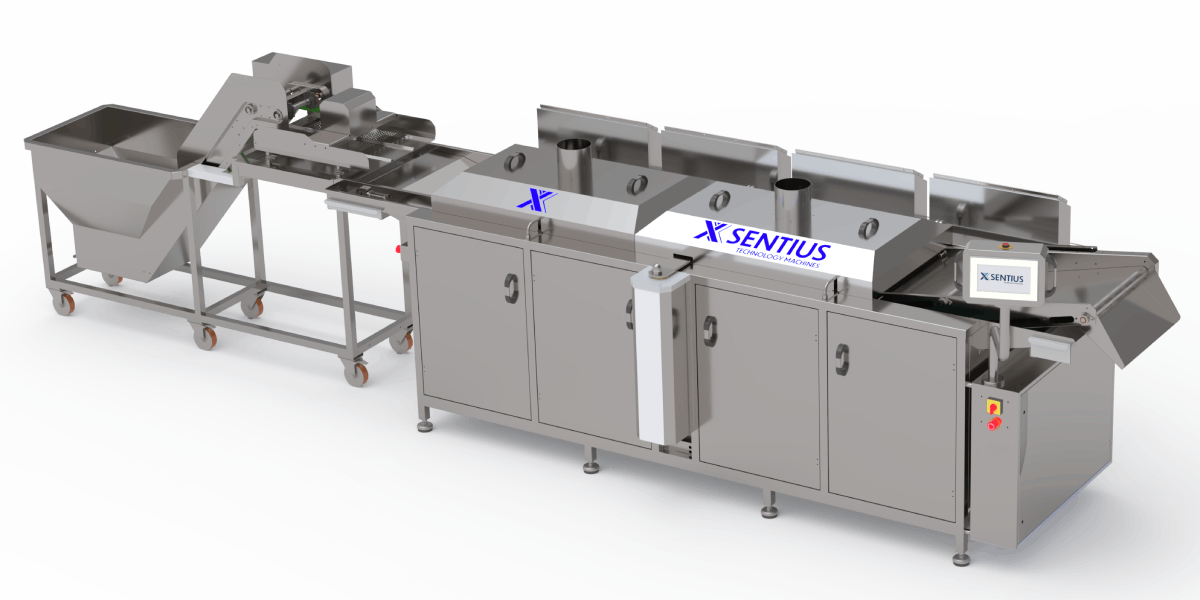

Deep Fryer

About the Product

The loading conveyor has a capacity of 350 kg and ensures even frying by distributing products through vibration. It has an average frying capacity of 300 kg of product per hour. The machine, with a 180-liter oil capacity, is equipped with a conveyor and dual heat control systems. The oil level can be monitored on the screen.

The machine features four filters: Filter No. 1 is a sediment trap, Filter No. 2 is a micron trap, Filter No. 3 consists of enclosed special filters, and Filter No. 4 is a cloth filter. These filters help keep oil cells healthier. The recipe-registered machine allows for unlimited recipe storage. The premix heating system ensures gas savings.

Industrial frying machines are essential equipment for restaurants, cafes, and fast-food businesses. Their high capacity allows for large quantities of frying in a short time. Automatic temperature control systems maintain the oil at the ideal temperature, ensuring both energy savings and perfectly cooked food. Modern frying machines are equipped with oil filtration systems that extend the oil's lifespan and provide healthier frying results.

-

Suitable cooking modes for various products (potatoes, chicken, fish, etc.)

-

Built-in oil filtration systems

-

Automatic shut-off and overheat protection for safety

-

Robust and durable stainless steel construction

-

These machines deliver consistent high performance even in busy kitchens, enabling the preparation of fresh and delicious fried foods every time.

Physical Features | Technical Specifications | Structural Features |

| Premix heating system | Cooking capacity: 300 kg | PLC command system |

| Dimensions: 1750*2200*2000 mm | Air inlet: 8 bar | Completely stainless steel material |

| Special design bottom valve | Input voltage: 380 V 50 Hz | Automatic conveyor |

| Total power: 12 kW | Gas inlet: 20 mbar | Oil tank 1 capacity: 200 liters |

| Pre-installed menu settings | Gas consumption: 3.7 cubic meters | Oil tank 2 capacity: 250 liters |