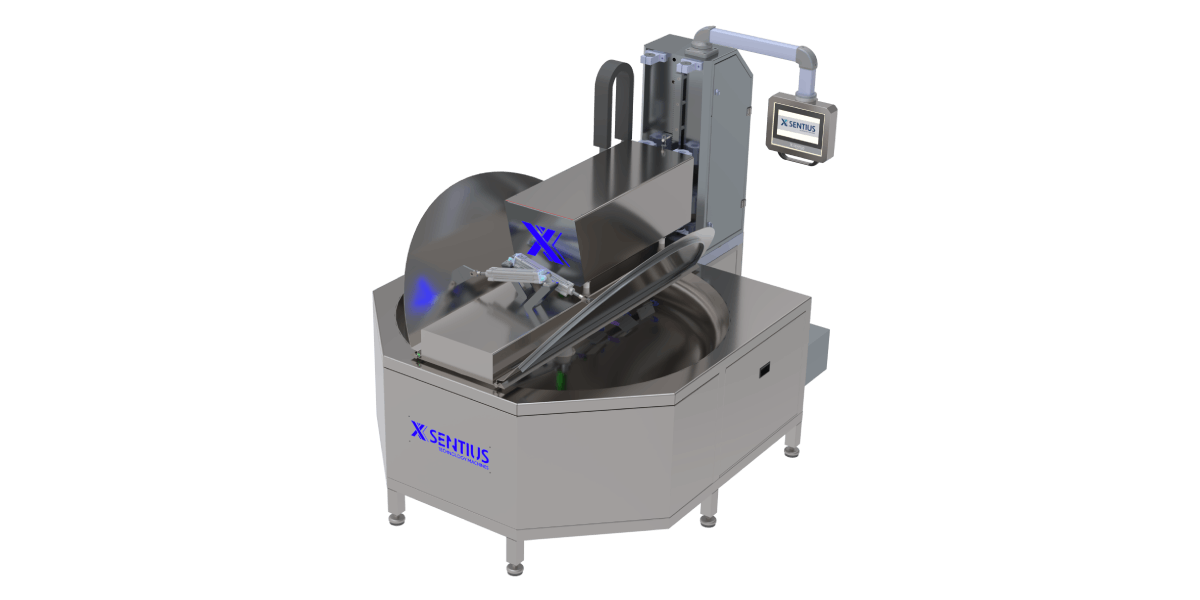

Automatic Rice Cooker

About the Product

The rice cooker has a capacity of 80 kg and can produce 1,000 servings in 45 minutes. It is used to prepare bulgur, noodles, fried rice, semolina halva, stuffed vegetables, and similar dishes. It is made of 304 stainless steel, and the boiler plate is made of 310 special heat-resistant material. The machine has 10 mm thermal insulation on its sides, and the heat-exposed areas are covered with 3 mm galvanized steel, with thermal insulation silicone applied between them. The specially designed bottom drain valve has a width of 2 inches and no blind spot, allowing hot pasta water to be drained quickly. The machine's upper lids are automatically designed and do not come into contact with the ground for hygiene purposes. A specially designed mixing arm is provided to prevent rice breakage. A filtration screen is added to the outlet to prevent residues from entering the waste drain during cleaning. A specially designed fully automatic premix system is used to achieve homogeneous heat. This system provides efficient heating with a mixture of 60% air and 40% gas. Thanks to the 250-liter hot water tank, there is no need to add water from outside during bulgur production.

Physical Features | Technical Specifications | Structural Features |

| Premix heating system | Cooking capacity: 80 kg | PLC control system |

| Dimensions: 1750*2200*2000 mm | Air inlet: 8 bar | Entirely stainless steel material |

| Special design bottom valve | Input voltage: 380 V 50 Hz | Automatic mixing |

| Total power: 12 kW | Gas inlet: 20 mbar | Water tank capacity: 250 lt |

| Pre-installed menu settings | Gas consumption: 2.5 cubic meters | Heat control and insulation system |

| Water inlet: 2 bar | 3-stage flame height |